Meiners Oaks is a small residential community northwest of Los Angeles, tucked into the Ventura River Valley between the Topatopa and Santa Ynez Mountains. Founded by German immigrant braumeister John Meiners in the 1870s, the town is just up the road from Casitas Springs (home to country music legend Johnny Cash in the 1960s) – and just down the road from the organic farms and health spas of Ojai.

Like 83% of California’s residents, the 4,000 people of Meiners Oaks depend on groundwater for their survival. The Meiners Oaks Water District serves those needs with production wells, all nestled along the unpredictable banks of the Ventura River. If even one of those four wells underperforms, it puts pressure on the entire system.

Well #4A was drilled in 2018, as a replacement for original well #4, and situated less than 100’ away. In its heyday, original Well #4 produced up to 800 gpm.

By the time of replacement, production had fallen off and the mild steel casing badly deteriorated.

Well #4A was drilled to a depth of 150’, with an inner diameter of 16”. The well was constructed of 304 Stainless Steel, with Roscoe-Moss Super-Flo Louvered perforations from 70-100’ and 115-130’.

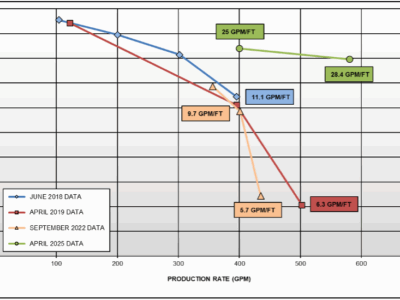

Unfortunately, #4A did not produce as desired. Initial performance (2018): 400 gpm, 36’ of drawdown, for a Specific Capacity of 11.1 gpm/ft. 2019 performance: 500 gpm, 80’ drawdown (right down to the bowls!), Specific Capacity 6.3. 2022 performance: 440 gpm, 77’ drawdown, Specific Capacity 5.7.

When Meiners Oaks wells do not produce sufficient volume to supply the District’s needs, water must be imported from Casitas Water District – at a much higher cost. Due to differing chlorination specifications, water from Casitas and Meiners Oaks cannot be mixed. So when local needs exceed local production, MOWD’s wells must be shut down entirely.

To avoid this added cost and inconvenience, the decision was made to redevelop Well #4A. The rehabilitation plan, designed by Curtis Hopkins of Hopkins Groundwater, included the WellJet® high-pressure hydrojetting process.

A feature of “river wells” in shallow alluvial aquifers is their tendency to produce sand that negatively affects performance and efficiency. To address this issue, the jetting process was combined with simultaneous pumping to evacuate fine grained material generated by jetting. Hopkins Groundwater and WellJet® (US Patent No. 8,312,930 B1) have successfully executed this type of approach on many similar projects over the years.

For Meiners Oaks #4A, WellJet® teamed up with Cascade Well & Pump of Santa Barbara, CA. Cascade has been drilling, developing, equipping and rehabilitating wells throughout Santa Barbara and Ventura counties since 1981. Prior to jetting, Cascade treated the well with a concentrated sodium hypochloride solution.

For WellJet®, the first challenge was gaining access to the well, which – due to having been constructed in one of the seasonal channels of the Ventura River – was situated on a raised platform. The District bulldozed an earthen ramp to allow the 40’ well truck to position in front of the platform and extend its 8’ boom over the center of the well. It was a very tight fit!

The WellJet® tool was tested on site and then lowered into the hole. Cascade’s crane was positioned at a 90° angle from the well truck and the submersible pump lowered so that it remained above the WellJet® tool. As a general practice, WellJet® prefers evacuation to take place as a separate step after jetting – to avoid the danger of the pump and/or column pipe becoming entangled with the high-pressure hose or the jetting tool itself. However, with shallow wells like this (150’), the risk was deemed acceptable – and in fact, thanks to the skills and focus of Cascade Well & Pump, there were no issues.

Another unique aspect of this project was that the WellJet® tool was run through the perforated area of the well a total of seven times – at pressures ranging from 13,000-18,000 psi. On most wells, a single WellJet® pass is sufficient to remove surface encrustation, open clogged perforations, and generate enough energy into the gravel pack and near-wellbore formation to restore production and efficiency. Sometimes, two passes are needed. On rare occasions – when deposits are known to be of tenacious mineralized content – a third pass is required. But seven? There comes a point after which excessive dwell time may damage old or compromised casing. Fortunately, Well #4A was relatively new (less than seven years), and constructed using robust Roscoe-Moss 304 Stainless Steel 0.125” slot Super-Flo Louvers. Hopkins Groundwater was confident that the well would not only successfully withstand this sustained jetting approach but benefit from it – and that it did.

During jetting and simultaneous pumping, discharge water featuring noticeable sand content was captured in a settling tank before being conveyed to an approved recharge area.

Following the combined jetting/pumping operation, Cascade did dual swab cleaning of the well screen and removed more of the fine silts that the jetting loosened up.

Results validated the program designed by Hopkins Groundwater: 580 gpm, drawdown of 20.4’, Specific Capacity of 28.4 gpm/ft. This represents a 400% improvement in efficiency over pre-rehab Specific Capacity – and 156% improvement over when the well was brand-new and producing only 400 gpm.

The value provided by the rehabilitation program is that, because of the improved output and reduced drawdown, the District can continue using Well #4A for a longer period of time during dry stretches when the water table drops – rather than having to shut down and switch over to the more expensive water imported from Casitas Municipal Water District.

“The goal was to provide a reliable source of water during seasonal and climatic changes in the aquifer,” Mr. Hopkins said. “We were able to achieve that goal.”

Justin Martinez, General Manager of Meiner Oaks Water District, added: “We’re super excited… To get 600 gpm with half the drawdown is pretty exciting.”

WellJet® is pleased to have played a role in this successful well restoration project.

Jetting Lined Wells

Jetting Lined Wells