The City of Downey’s Well #11 was drilled in 1994. Total depth was 980’, 20” ID, with Ful-Flo Louvered perforations from 400-440, 480-640, 680-800, 840-960 (440’ of total perfs, spread over 560’ of total well depth). Test pumping during completion yielded a robust 4,540 gpm, with 45’ of drawdown and a specific capacity of 100.

Over the next two decades, performance declined. By 2016, production was 2,572 gpm, with 86’ of drawdown and a specific capacity of 30. Static water level, which had been 65’ at the time of drilling, had dropped to 123’.

Downhole video revealed severe encrustation throughout the perforated areas, generally increasing with depth, heavy nodules, with perforations heavily or completely plugged and occluded.

A comprehensive rehabilitation plan was developed in concert with consulting firm Wood Rodgers, to include mechanical cleaning, chemical treatment airlift swabbing, and redevelopment via pump surging.

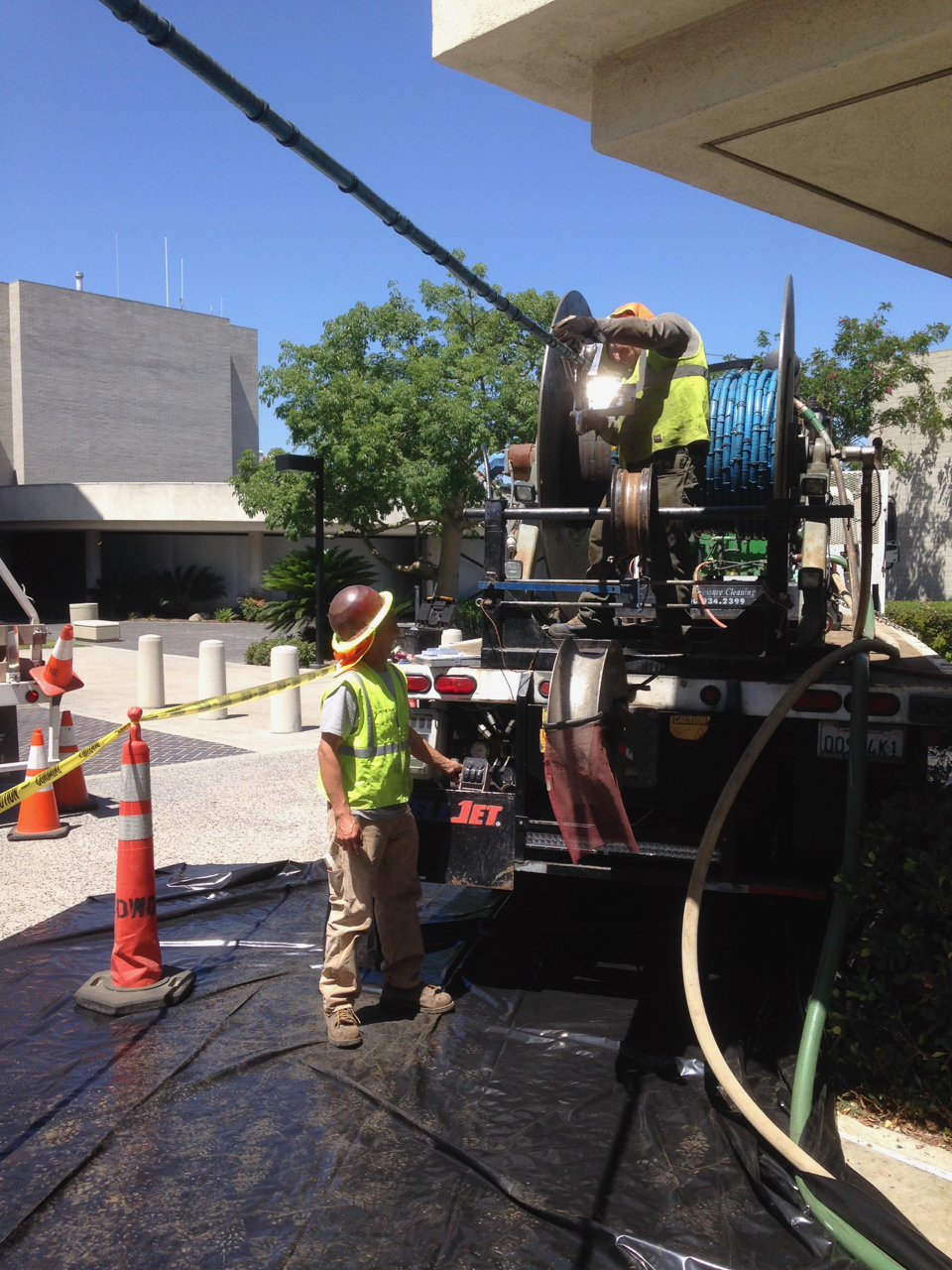

Layne Christensen was contracted by the city to perform the rehabilitation, and HydroPressure Cleaning, Inc. was tasked to handle the mechanical cleaning through its patented WellJet® process.

WellJet® utilizes highly pressurized water in a laminar flow to remove obstructions from inside the casing, open clogged perforations, and penetrate into the gravel pack and near-wellbore formation to break up harmful deposits that impede free water flow.

Because heavy encrustation covered much of the casing, a Casing Inspection Thickness Measurement (CITM) was performed by Pacific Surveys, to gain further data on the well’s integrity.

The CITM revealed areas of potential casing thickness decrease from 230’-260’, and 800’-840’. WellJet® adjusted the parameters in its process, to reduce the possibility of exposing any existing casing damage.

Because the well is situated inside a building with limited access, WellJet® built a quadropod to position the high-pressure hose wheel above the well (instead of its usual practice of a telescoping boom arm off the back end of the well truck).

Click or tap the images below to view larger images:

Jetting was performed over a period of three days.

Following jetting, more than 300’ of fill entered the well. While it is common for WellJet® to generate some fill, the total amount in this case was rather large – which raised the question of whether a break or other form of breach in the casing had been uncovered.

Layne removed the fill via airlifting. There was no break; the well had just been very badly plugged up!

Over the following weeks, Layne performed dual-swab airlifting and the other needed procedures to complete the rehabilitation process.

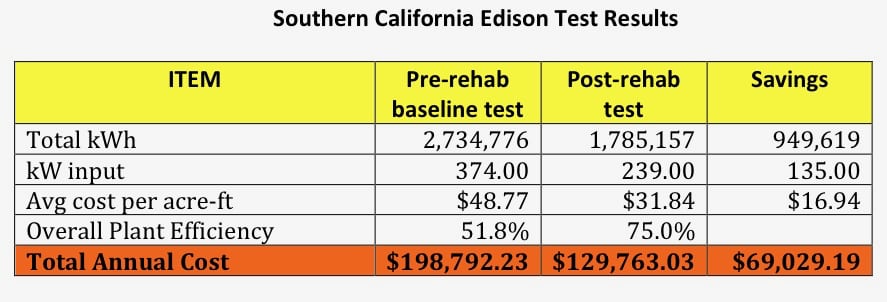

How did it all turn out? According to a Downey spokesperson: “We had fantastic results for the Well 11 rehab, particularly on energy savings.”