In many ways, the Van Norman Complex of the Los Angeles Department of Water & Power is the nerve center of the region’s vital infrastructure. Nestled in the foothills of the San Gabriel Mountains, surrounded by the ribbons of asphalt and concrete that pulse with commercial and civilian traffic, it is here where the Los Angeles Aqueduct completes its 400-mile journey from the Owens Valley high in the Sierras.

Here is where up to 600 million gallons of water per day are treated, in the Los Angeles Aqueduct Water Filtration Plant – before flowing through faucets and spigots from Boyle Heights to Beverly Hills.

There’s also a substation powerhouse here. The Metropolitan Water District has a treatment plant nearby to the west, and the Los Angeles Police Department has a training facility just south of the reservoir. In and around the vicinity, the Los Angeles Fire Department conducts Search-and-Rescue training.

In addition to all this important activity, in 2015 LADWP drilled a pair of exploratory deep artesian wells – Van Norman #1 and Van Norman #2. The wells are approximately 1,400’ deep, with 10” diameters.

The wells were drilled in response to the Los Angeles Mayor’s Executive Directive No. 5, mandating the development of local supplies. LADWP is trying to find more sources of clean drinking water, and in this case, it is clean groundwater. It is within the San Fernando basin, is not contaminated, and therefore does not require additional treatment.

In 2017, after the wells had sat idle for more than a year, LADWP engineers designed the development protocol for VN #1 and VN #2, to complete the development process for both wells. The engineering consultant firm Kleinfelder was hired to oversee and analyze the development efforts, to be executed by the drilling-and-rehabilitation team at Layne Christensen.

Downhole video revealed areas of residual drill mud plugging perforations in both wells. WellJet was brought in to use its patented high-pressure water-jetting technique to remove hardened mudcake from inside the well screens, and deliver energy out through the gravel pack, to the near-wellbore formation – as an aid in breaking up all the harmful deposits that had accumulated during the lengthy idle period.

One particular challenge on this project was maintaining control over discharge water during the rehabilitation process – always an issue with artesian wells. This was solved by installing suction hose at the well access ports, and pumping off the overflow into a series of Baker settling tanks.

WellJet began its work with VN #1.

WellJet on site, VN #1

LADWP Safety Meeting

WellJet always tests tool on site before going downhole

Kleinfelder observes tool test

Baker tanks at extreme left, suction pump in center left.

Jetting the entire perforated area of each well required three days.

Following jetting, Layne continued the development process with several days of swabbing, airlifting, surging and test pumping.

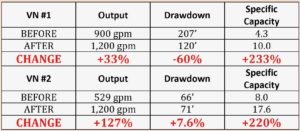

Results were quite positive:

Layne and WellJet have enjoyed successful collaboration on other projects for LADWP, in addition to other water suppliers and well owners in California.